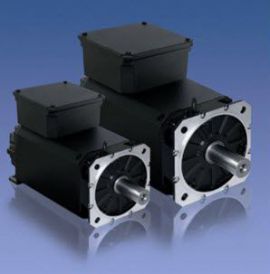

AC disc motors DSM

Three-phase disc motors are available in two versions — coreless and iron core.

Coreless

- High overload capacity due to coreless motor winding

- High torque via NdFeB permanent magnets

- High performance in a small unit with an extremely short design

- Detent-free and very quiet thanks to coreless motor winding

- Virtually constant torque over a wide speed range

Iron-core

- High torque via NdFeB permanent magnets

- Can be used as a torque motor thanks to variable winding design

- Very high performance in a small unit with an extremely short design

- Low detent torque due to rotor optimization

- Optionally available with brake, tachometer, encoder, gearing

Your benefits

- Very quiet

- Virtually detent-free

- Low-inertia and highly dynamic running characteristics

- Space-saving, shallow design

- Low maintenance requirements

- Special version as a high-torque drive

- Performance can be doubled using a second stator

- For small and medium power up to 6300 W

- Optionally available with tachometer generator, pulse generator, holding brake and gearing

- Insulation class F, protection class IP44, higher protection class available on request

Technical data - DSM

| PN [kW] | nN [min-1] | J [kgcm²] | M0 [Nm] | |

| DSM-115 N 2) | 0.41 | 3000 | 10 | 1.3 |

| DSM-115 N/I 1) | 0.205 | 3000 | 10 | 0.65 |

| DSM-117 N | 0.47 | 3000 | 10 | 1.5 |

| DSM-130 N | 1.4 | 3000 | 18 | 4.5 |

| DSM-150 N | 2.26 | 3000 | 40 | 7.2 |

| DSM-170 N | 3 | 3000 | 60 | 9.6 |

| DSM-190 N | 4.5 | 3000 | 90 | 14.4 |

| DSM-190 N2/L | 6.3 | 1000 | 120 | 60 |

DC disc motors GDM

Baumüller DC disc motors are permanent-magnet motors with coreless rotors and drum-shaped commutators, giving them low-inertia and highly dynamic running characteristics. They are easy to control over their entire speed range and maintain exact concentricity, even at very low speeds below one revolution per minute.

These motors are characterized first and foremost by their space-saving, shallow design. In their shortest construction type, only 39.5 mm of installation space is required in the axial direction. In terms of the installation space in relation to the achievable engine power, the GDM 12 N motor is the slimmest and most compact disc motor in the world.

Your benefits

- High overload capacity thanks to robust wire wrap with drum-shaped commutator

- High torque via NdFeB permanent magnets

- High performance in a small unit with an extremely short design

- High dynamics due to high overload capacity

- Very low torque ripple due to collector lamellation

- Very low carbon brush wear due to armature inductance

- Detent-free due to coreless rotor

- Virtually constant torque across a wide speed range

- Easily controllable

- Optionally available with brake, tachometer, encoder, gearing

Technical data - GDM

| PN [kW] | nN [min-1] | J [kgcm²] | M0 [Nm] | |

| GDM-10 F | 0.1 | 4800 | 1.2 | 0.2 |

| GDM-10 N | 0.142 | 3000 | 1.2 | 0.45 |

| GDM-12 N | 0.147 | 2000 | 2.7 | 0.7 |

| GDM-12 Z | 0.072 | 3000 | 2.1 | 0.23 |

| GDM-75 Z | 0.016 | 3000 | 0.5 | 0.05 |

| GDM-80 F | 0.044 | 4200 | 0.7 | 0.1 |

| GDM-80 N | 0.071 | 2700 | 0.7 | 0.25 |

| GDM-9 K | 0.032 | 3000 | 0.6 | 0.1 |

AC disc motors DSM - DC disc motors GDM - Motor DSM Baumuller

- AT2E

- Baumuller

- Bircher

- BCS Italy

- Bernard Control

- Beckhoff

- Beijer

- CS Instruments

- CEIA

- DECA WELD

- Elau Schneider

- Fireye

- Finetek

- Gastron

- IBA

- Insert Deal

- Knick

- Koganei

- Keofitt

- Keller - Its

- Kiepe Elektrik

- Kometer Flowmeter

- Lapar Valve

- Mark - 10

- Matsushima

- Minimax

- Nireco

- Ohkura

- Pavone Sistemi

- Pora

- Red lion

- Riels

- SOR

- Staubli

- TDK Lambda

- Teclock

- Vega

- YTC (Young Tech)

- Wago

- FOX THERMAL

- ORBINOX

- Clyde Pneumatic Conveying

- KREBS - RIEDEL

- PCI Instrument

- CEMB

- BARKSDALE

- INTORQ

- SITEC

- Spohn Burkhardt

- Emerson

- KSR KUEBLER

- Dosatec SA

- Thwing-Albert

- OKAZAKI

- TEK TROL

- NAGANO KEIKI

- Danh mục khác

-

Trực tuyến:3

-

Hôm nay:228

-

Tuần này:228

-

Tháng trước:14046

-

Tất cả:2490531

Giao hàng miễn phí.

Giao hàng miễn phí.

Thanh toán linh động.

Thanh toán linh động. Bảo hành 12 tháng.

Bảo hành 12 tháng..png)